Choosing a hinge

Constant (K)

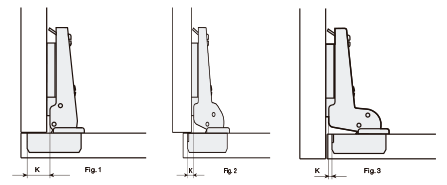

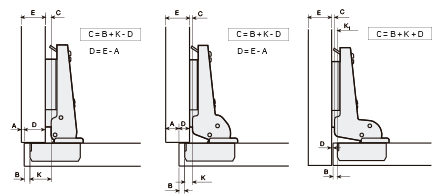

The door is usually assembled on the side in three different ways (fig. 1, 2, 3). Each of these assemblies has its own constant. This constant is the distance between the arm depth and the corner of the cup with the hinge closed. As shown in the figures, each assembly has its own constant, which is set by the different arm heights..

- (1) Full overlay arm: it has the highest constant to overlay the whole side.

- (2) Half overlay arm: intermediate constant to overlay part of the side.

- (3) Full inset arm: minimum constant for embedded doors.

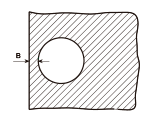

Distance to the edge (B)

This is the distance from the 35-mm cup hole to the door edge. This value is variable according to the margins for each type of hinge. These margins are specified on the hinge diagrams in the catalogue.

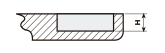

Cup drilling depth (H)

This is the minimum required drilling depth for a hinge cup. Depending on the hinge, this value may be 10.5 or 12.5 mm..

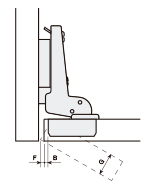

Lateral door displacement (F)

The front-side corner of the door has a slight lateral displacement. This displacement must be respected in order to open the door. Main factors affecting this displacement are door thickness (g) and distance to the edge (b). See charts in every case.

Height of the plate

These are the different heights of the mounting plates in order to correctly overlay the door on the side.

Calculation of the height of the plate (C)

The chocks are calculated according to three variables:

- (a) The hinge constant (K).

- (b) The distance from the drill in the door (B).

- (c) The degree of overlay of the door on the side in the cases of full and half overlay, or the gap between the door and the side for the full inset version (D).

In these conditions, the formulas used to calculate the heights of the plate in the three different types of arm are shown below.

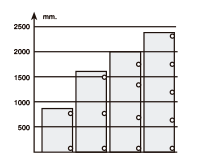

Required number of hinges and how to arrange them on the door

The number of hinges required depends on several factors, including the type of hinge, the door's weight, height and width, etc. For this reason, and given the number of variables, please check the charts for an estimate (next to the diagrams in the catalogue).

It is advised to locate upper and lower hinge at less than 80 mm from each edge. When dealing with low or particularly wide doors, the distance to the edges must be reduced as much as possible.

We help you to select the most appropriate product.